Many in the military made a virtue of necessity: they increasingly began to enjoy the new technique and perfected the skills and manual dexterity they needed to roll their own. With the growth in demand, expansion was clearly on the cards at the end of the war. Schoeller & Hoesch decided to develop its company Obenaus & Maier in Cologne into a production site. The site's proximity to the densely populated Ruhr may also have played a role in the choice of location, as the majority of the “self-rollers” were working class.

GIZEH’s pre-history began in 1881 with the foundation of the “Schultz & Cie.” pulp mill in the northern Black Forest, which began producing cigarette papers in 1905. The company, from then on operating under the name “Seiden- und Zigarettenpapierfabrik Schoeller & Hoesch GmbH”, quickly developed into a specialist in the manufacture of quality rag paper; in the early 1920s, it was already one of the world’s leading cigarette paper manufacturers. The key driver of its success was increasing cigarette consumption at the turn of the 20th century. A trend that strengthened further during the First World War. As the supply of filter cigarettes could not always keep up with demand, soldiers often turned to loose tobacco.

The GIZEH factory is born

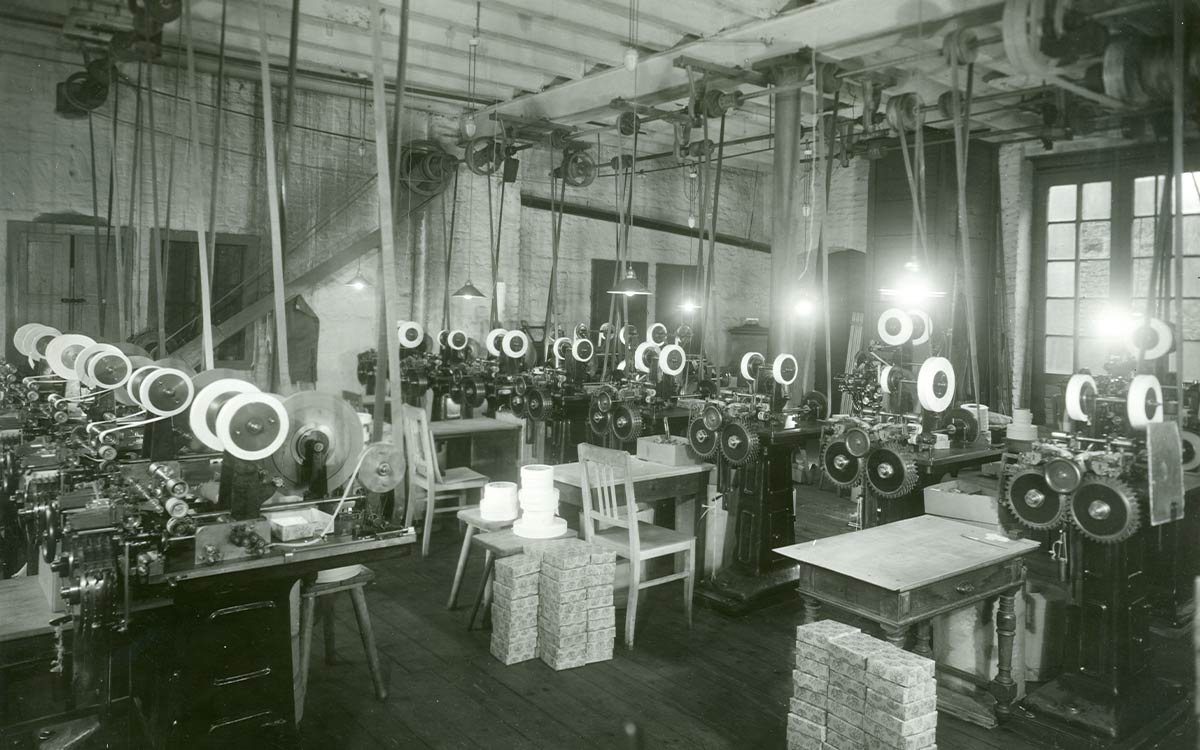

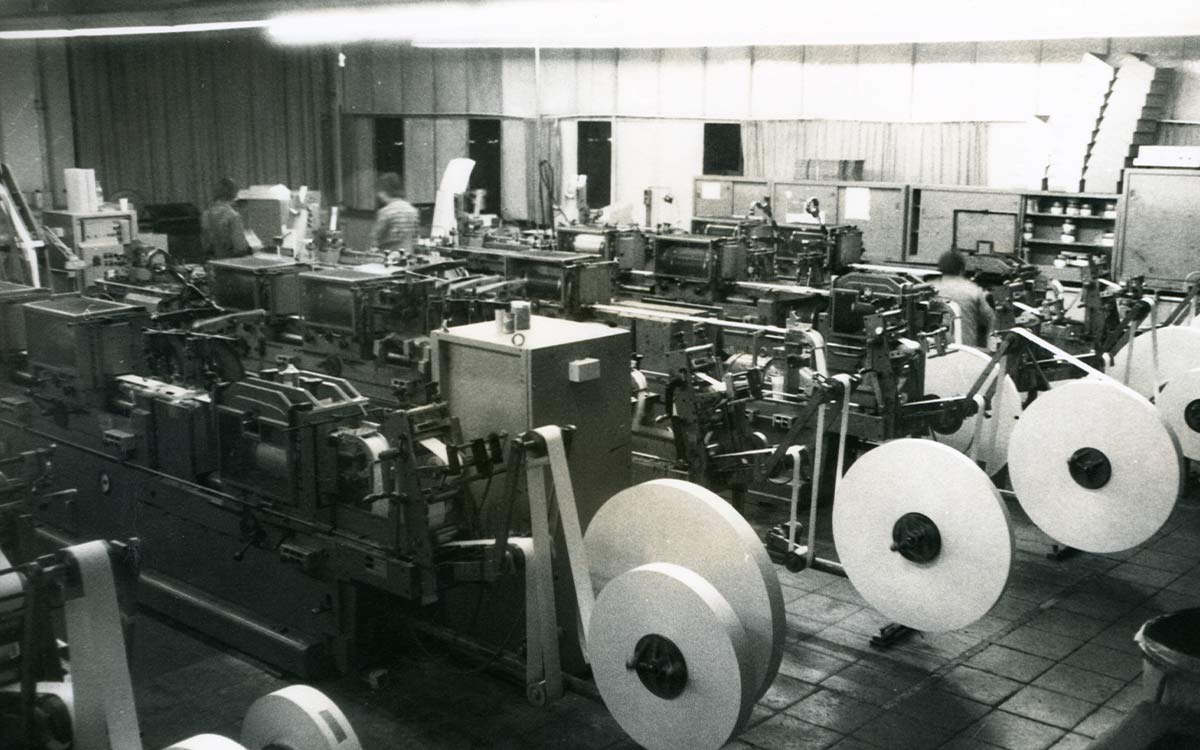

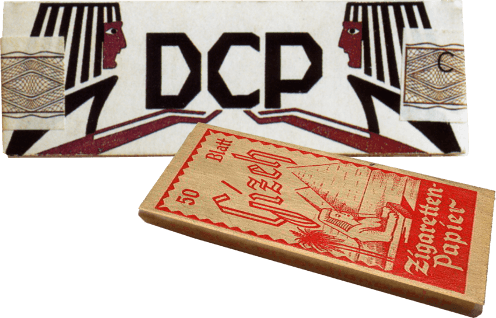

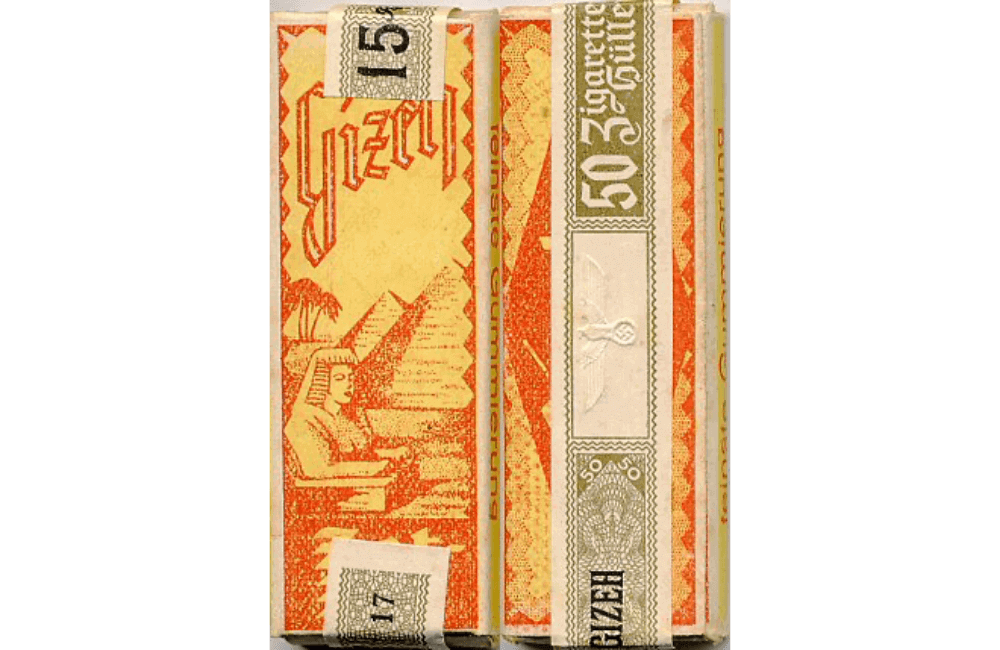

On 2 January 1920, the time had finally come. With the entry of “GIZEH Zigarettenpapier-Verarbeitungs-Gesellschaft m.b.H.” in the commercial register, the GIZEH factory was officially born. At first, only flat packs of cigarette papers were available; later, folding or “Zig-Zag” packets were added. High demand finally led to the recruitment of additional workers and the purchase of new cutting, booklet-making and gumming machines. With the purchase of a residential and factory building just outside the old town of Cologne, in 1923, it was possible to achieve noted improvements in production conditions. Two successful brands were the main contributors to this positive development: “Deutsche Cigaretten-Papier” (DCP), which was already being produced by Schoeller & Hoesch, and the new own brand “GIZEH”; a brand highly evocative of its era, with the world-famous Egyptian pyramids reflecting the widespread fascination with the orient at the time.

GIZEH in the period of National Socialism

In May 1933, Dr Vincenz Wachter, previously an authorised representative and tax consultant for Schoeller & Hoesch, took over the management of the firm. Max Maier and Sabine Obenaus first gave up their management roles, and then left the firm entirely by emigrating to the USA in 1937. In contrast to many other Jewish businesspeople, however, both were generously compensated and, until the end of the war, received a share of the profits for every booklet sold through a special account set up for this purpose. The initial economic upturn in this period led to marked increases in turnover among German cigarette paper manufacturers, who employed around 2,000 people at this time. Despite striving for economic independence, Germany remained the largest tobacco importer in the world in the 1930s. Every year, 100,000 tonnes were imported, above all from Greece, Turkey and Bulgaria. In addition, the Nazi party’s policies with regard to consumption emphasised moderate, affordable pleasures and protected the tobacco industry from legal restrictions.

GIZEH-Werk Dr. Wachter & Co

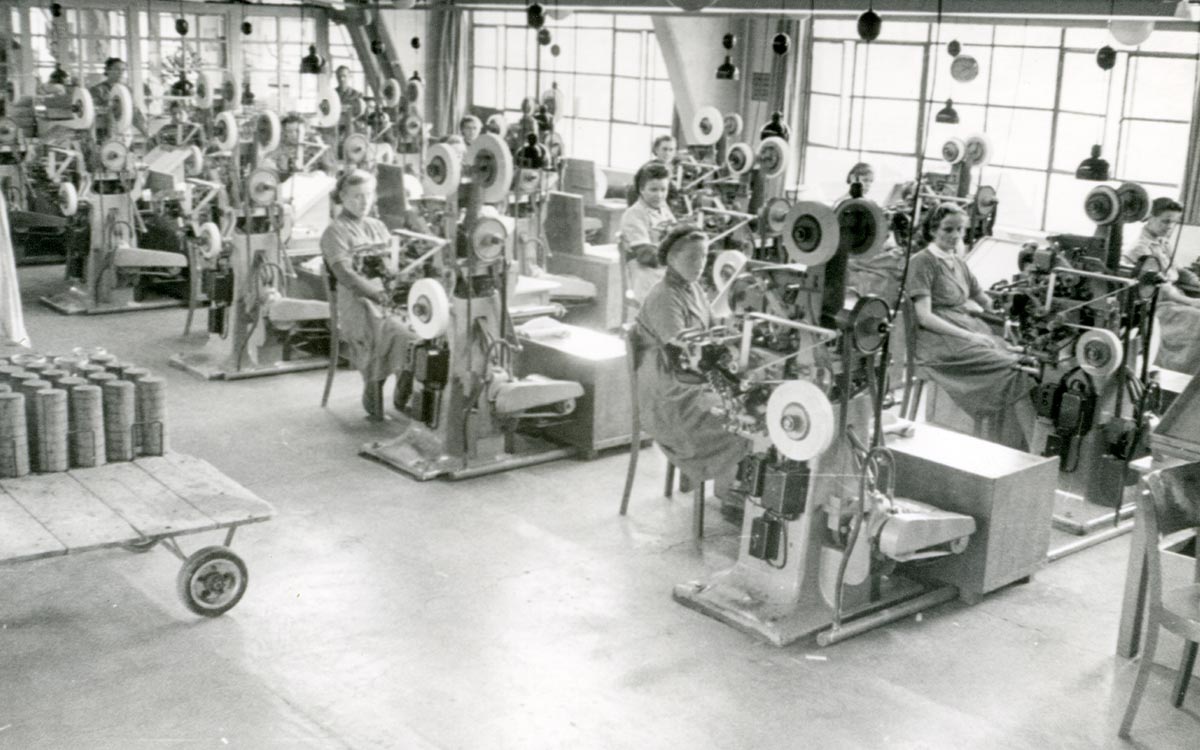

GIZEH was therefore able to expand unhindered, using the years from 1933 to 1938 to increase the size of the premises and carry out technical modernisation. With the transfer of production to Cologne-Raderberg, booklet production moved onto high-performance machinery. Additional gumming, cutting and insertion machines could easily be incorporated in the larger halls. Having achieved semi-industrialised manufacture at its old premises, GIZEH finally developed into a true industrial operation. With the expanded machinery, it was now possible to include cigarette tubes in the production program.

Under the new name “GIZEH-Werk Dr. Wachter & Co.”, the company became a Kommanditgesellschaft (limited partnership) in 1937. With its improved machinery and equipment, GIZEH was also able to take on additional job order production tasks, becoming the “extended workbench” for various producers and distribution offices in the 1930s. These included the traditional manufacturer Jordan, the branch office of Wiener Austria in Munich, Meyer in Berlin and the Landfried tobacco factory in Heidelberg. From 1938, the GIZEH factory also produced booklets under licence for Abadie.

The war economy and production relocation

This was also the case for the GIZEH factory, which was also only able to produce under difficult conditions. In 1942, the increasing threat of air raids led to a partial relocation of booklet manufacture from Cologne to Lorraine, where approx. four million booklets, i.e. 40,000 boxes, were produced every month. However, the Lorraine production site was only a brief interlude in the company’s history; it was lost to Allied occupation in December 1944. In the meantime, fears for the Cologne headquarters became true. Two heavy air raids in summer 1943 and autumn 1944 destroyed the multi-storey building and all the manufacturing facilities. Five employees died among the rubble.

At the same time as production was relocated to Lorraine, another production facility was also opened in the Bergisches Land. GIZEH rented out the Gaststätte Neuhaus in Bergneustadt, whose splendid ballroom offered plenty of space for temporary manufacture. From 1943, the gas gumming, flat cutting and booklet-making machines were gradually moved there, and production started in 1944. In typical fashion for ad-hoc wartime measures, the ballroom had only been rented from Monday to Friday, with production mostly limited to the mornings. In the short term, this arrangement made it possible to compensate, at least in part, for the loss of other operating facilities. With a production volume of approx. two million booklets a month, i.e. 20,000 boxes, a satisfactory result was achieved even under these difficult conditions.

In addition to the political and economic turning point in 1945, GIZEH also experienced a turning point in terms of its personnel, location and legal form. After the death of managing director Dr Wachter, in autumn 1945, old hands Kurt Breidenbach and Josef Herp took over the reins at the stricken cigarette paper specialist. In January 1946, the reorganised company was converted into a GmbH (limited liability company). Production in Bergneustadt continued, though with greatly reduced personnel and machinery compared to the pre-war era.

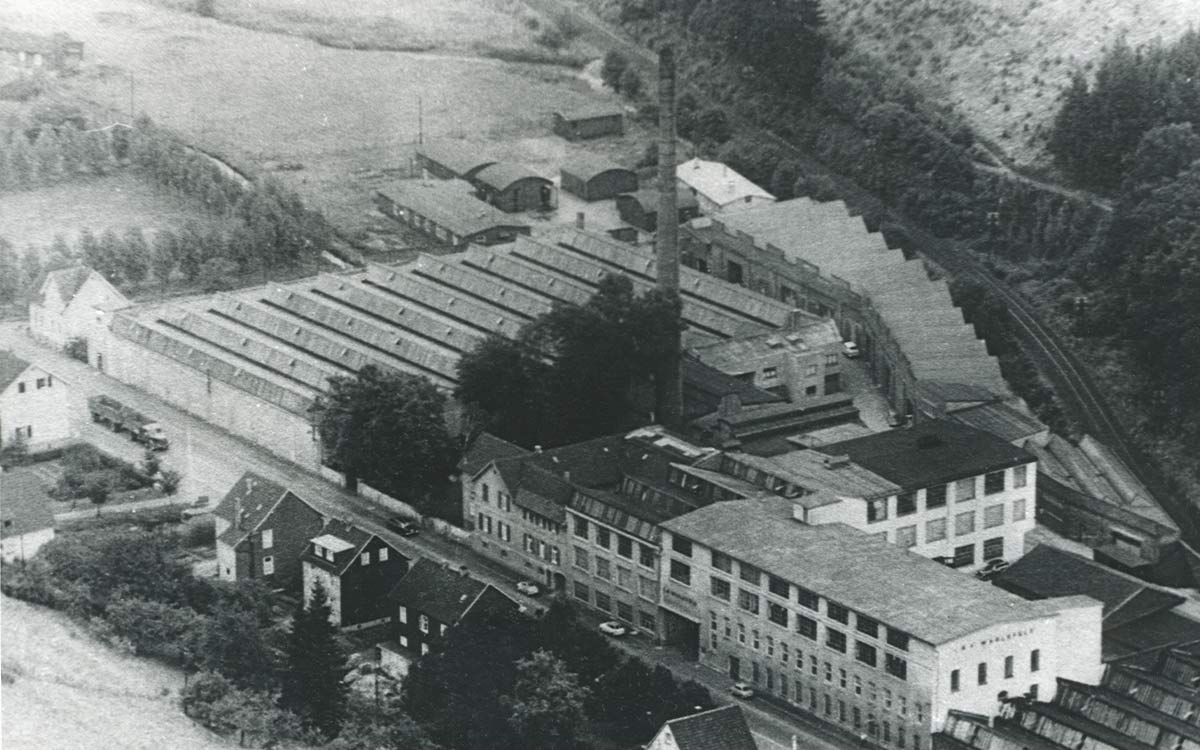

However, there was no reason to worry about a lack of demand. Directly after the war, cigarette paper booklets were much-sought-after goods on the black market. On this basis GIZEH’s prospects soon began to look up. Following the currency reform in 1948, the company finally found suitable premises again by renting a part of the business from the nearby textile company K.F. Wahlefeld. The Bergneustadt operation was able to increase its market share for cigarette paper booklets to approximately 20% by 1950, with sales focused in north Germany and the Ruhr.

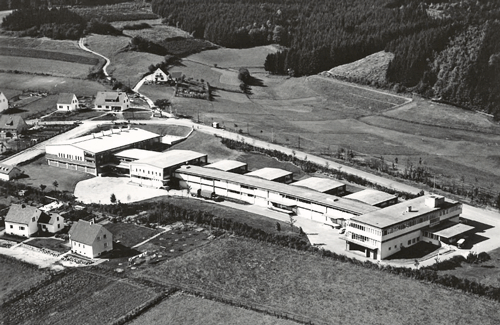

Construction progressed rapidly, and not even the snowy winter of 1954/55 could seriously threaten the progress of the development. Finally, in late autumn 1955, the successful move to the northern outskirts of the city was complete, laying the foundations for the development of a strong member of the “Mittelstand”, Germany’s class of small to mid-size companies, which would become one of the largest operations in the sector and the entire region.

“History is more than past events, history is created layer by layer – history is the foundation on which we stand and build.”

Hans von Keler, protestant theologian

Diversifying the portfolio

The rooms and halls of the newly built factory also allowed the diversification of the product portfolio. In the mid-50s, GIZEH began to make its first attempts to expand its product range with lipstick blotting papers, eyeglass cleaning cloths and refreshing towelettes.

Soon, however, management began to focus entirely on the booming punched card industry, where the company had to compete with its competitor IBM, which at first seemed to be superior.

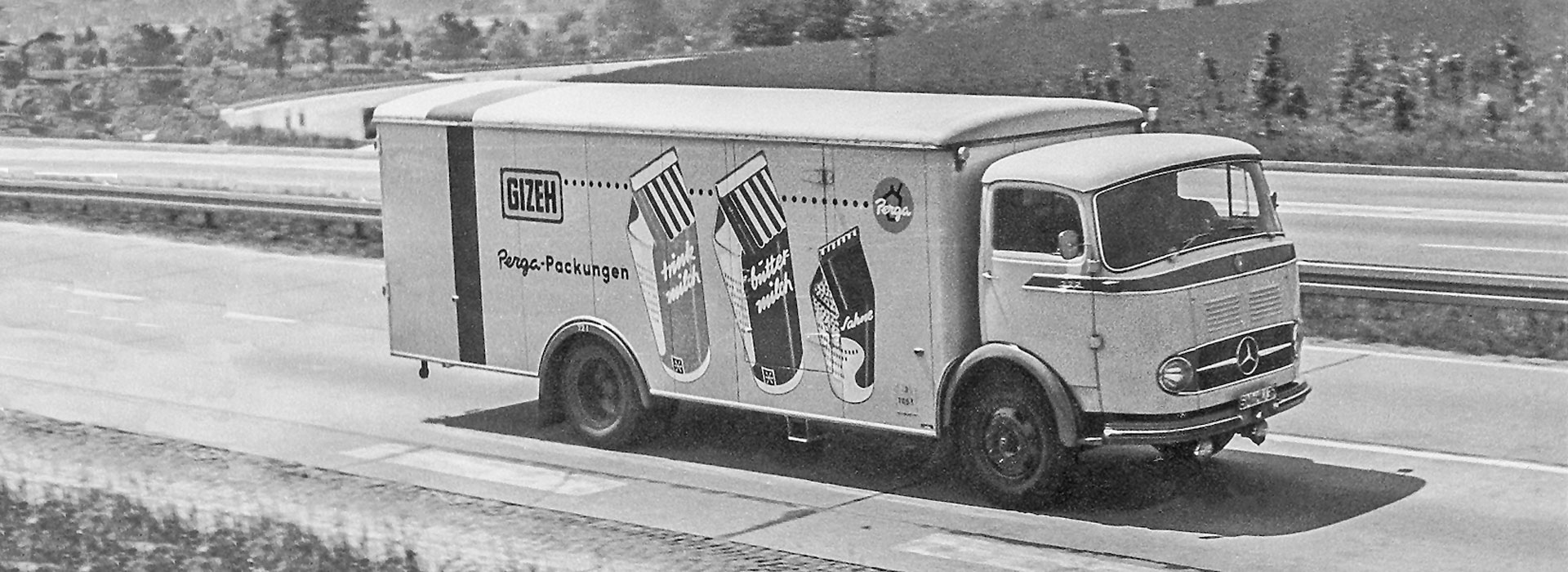

In the 1950s, as milk bars became much-loved youth hangouts, GIZEH was also heavily geared towards milk and milk packaging. At the same time, food retail was moving increasingly towards self-service. Innovative packaging solutions were needed to protect goods and encourage purchases. In cooperation with Jagenberg, a company from Düsseldorf, GIZEH entered the “Perga” packaging business at the end of the 50s, which would soon establish itself in the dairy industry. A layer of paraffin ensured a tough, impermeable and resilient package – just what producers wanted.

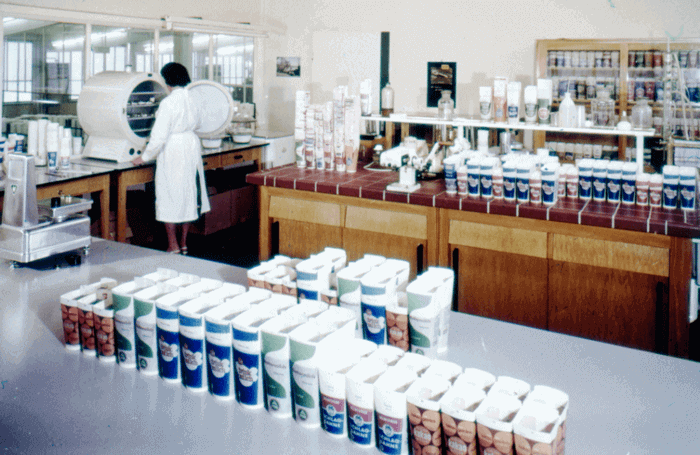

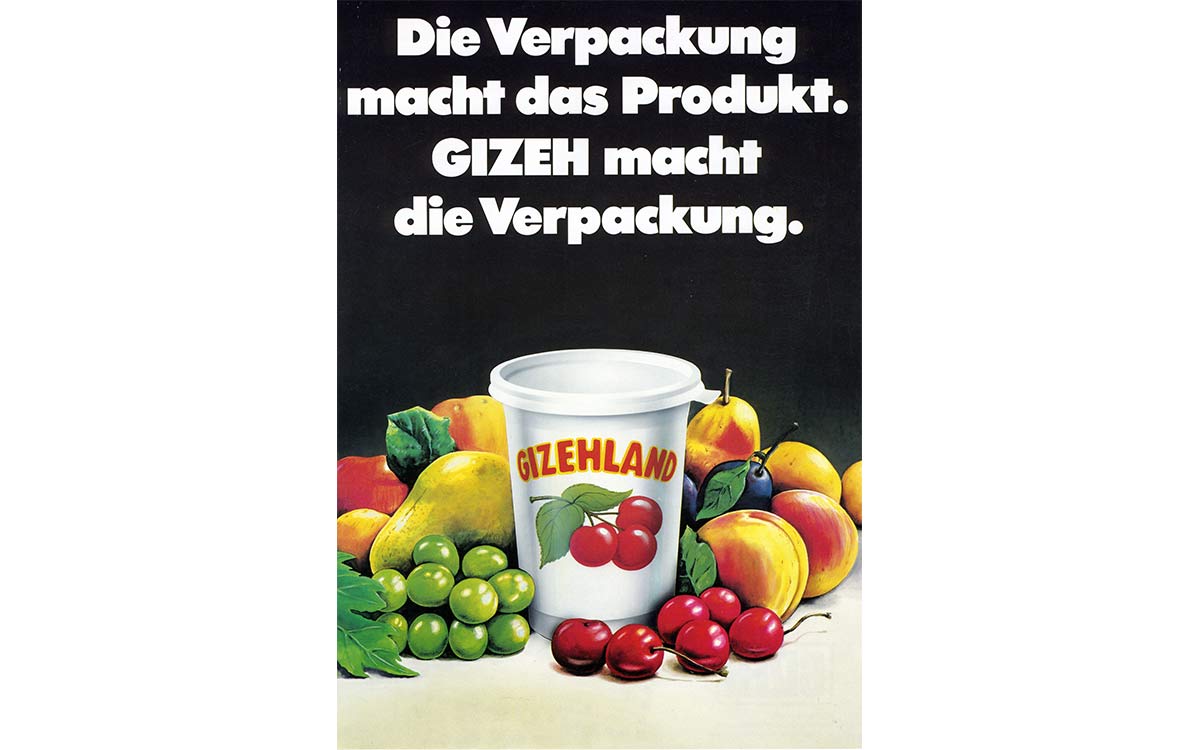

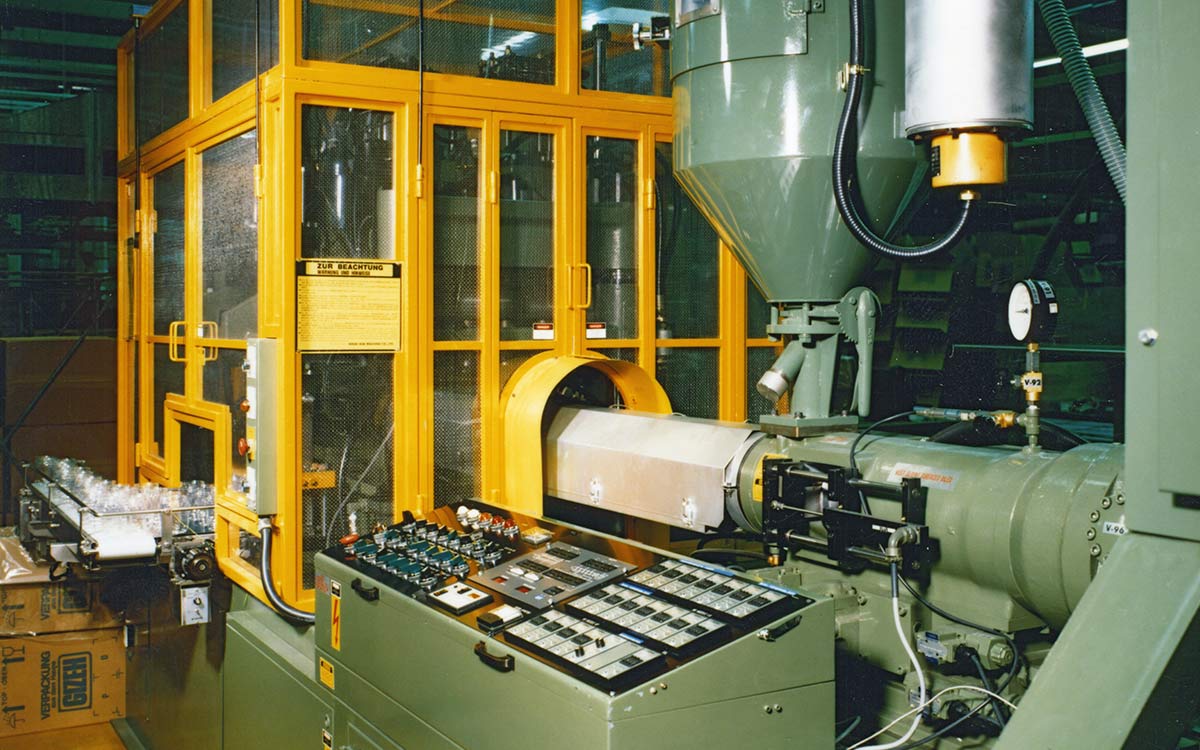

The plastic tub

With the experience it had gained in the plastics sector, GIZEH began to produce thermoformed packaging for milk and dairy products from 1966. Thanks to the plastics boom, a new factory was built in 1968 with 5,500 m2 of space and room for a subsequent expansion of production. This made it possible to produce plastic tubs for quark, cream and milk with volumes up to 5 l. By including a barrier layer, it was also possible to protect sensitive contents from possible fermentation processes. With these innovations, GIZEH was able to become one of the leading packaging manufacturers in the dairy sector remarkably quickly.

At this time, the decisive manufacturing and processing techniques were established that allowed the production of a wide variety of packaging variants. Into the 1970s, research and industry developed the most important polymers for packaging applications: PVC, polyamide, polypropylene, polyethylene, polystyrene and PET. One of the reasons why plastics became such a success was that they combined a variety of properties such as lightness, robustness, flexibility and outstanding impermeability. Whether in blister packs for medication, jars and bottles for cosmetics or foil packaging for food: the range of uses was always growing.

Plastic packaging for the dairy sector

And so the company continued its rise. With the construction of a new plastic processing facility, GIZEH set a new benchmark for Germany, and by the end of the decade had become the major supplier to the dairy sector, with a production volume of almost a billion tubs. Over the course of the 1970s, new packaging shapes and application-oriented specialties were constantly added. Specific volumes, dispensing options and variant openings also improved the quality of the range. The development of tub production in the 1970s was crowned by a real highlight: in 1979, Nestlé and GIZEH together brought the first 5-minute meal to market.

In addition, in 1974, a range of single-use tableware was made available and a new production site opened in Bouxwiller, France. The ease of use, physiological harmlessness and hygienic advantages of the tableware range ensured rapid market penetration. The stylish, modern kitchen of the 70s also included increased use of the deep freeze. While in 1960 every German household ate an average 830 grams of frozen food, by 1970 consumption had risen to over 10 kilos. To meet the growing need for user-friendly frozen food packaging, GIZEH developed various solutions, predominantly produced on the basis of cold-resistant polystyrene.

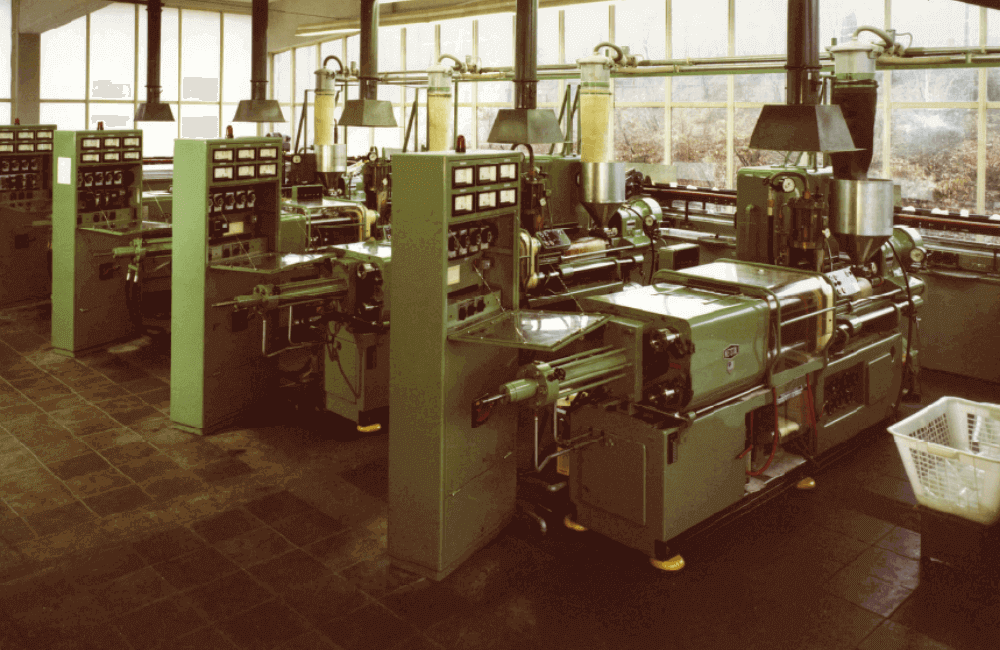

Becoming a punched card specialist

Alongside efforts to acquire new markets, GIZEH also stood firm in its established range of goods. By 1970 the company had grown into one of the largest producers of punched cards in the country, with a monthly production volume of 180 million cards. A whole range of special formats was added: short cards, special oversize cards, punched card sets, transdata cards (continuous strips) and not least OMR cards. OMR stands for Optical Mark Recognition and allows the optical processing of marked lines using computer-aided systems. In order to stay competitive in punched card manufacture, a further location was rented in Berlin-Neukölln in 1975. This step came quite late – perhaps too late, as the lightning-fast development of computer technology soon made punched cards a niche product.

The result of these developments was a drastic tax increase of 39% on cigarettes in 1982, leading to a marked increase in people rolling their own. A stroke of luck for GIZEH, as it commanded around 50% of the West German market for roll-ups at the time. This allowed production capacities to be further expanded and Cigarettenpapiermanufactur GmbH (CIMA) to be founded in 1983 in St Peter am Wimberg, a town north of Linz.

The 1981 foundation of an independent tool factory in Switzerland promised yet further autonomy for GIZEH. WEMABAG Schlatt AG produced complex dies and moulds for the large-scale injection moulding and thermoforming of plastic containers. Using the tools that were produced here, flexible adjustments could be implemented with the shortest possible setup time. For optimum capacity utilisation, competitors were also supplied with standard tools.

Another innovative packaging material that was on the verge of a major breakthrough in the early 1980s was the PET bottle. At GIZEH, the focus was above all on the development of bottle-like wide-necked containers with a screw or snap closure – a new product for the European packaging market. By the end of the decade, GIZEH had established itself successfully on the market and produced a wide range of wide-necked PET containers in various standard shapes and sizes, with an extensive range of lids to match.

Market expansion in Eastern Europe

The company moved further east in 1994 with the opening of a Polish operation in Łaskarzew, south of Warsaw. In 1997, this facility was replaced after the purchase of a new production site in Tarnowo Podgórne. In the direct proximity of the industrial centre of Poznań, this site went on to produce plastic tubs and tableware. Only a few years after its entry on the market, GIZEH had become one of the largest producers of dairy packaging in Eastern Europe. In addition to Poland, it supplied to Russia, Ukraine, Belarus and the Baltic States.

In 1991 GIZEH strengthened its existing data medium division together with Fleischhauer, a printing house steeped in tradition, with a new plant in Bochum. One year later, it was already producing more than four billion tickets and labels for car parks, public transport, industry and retail. This made Fleischhauer-GIZEH one of the world leaders in this sector.

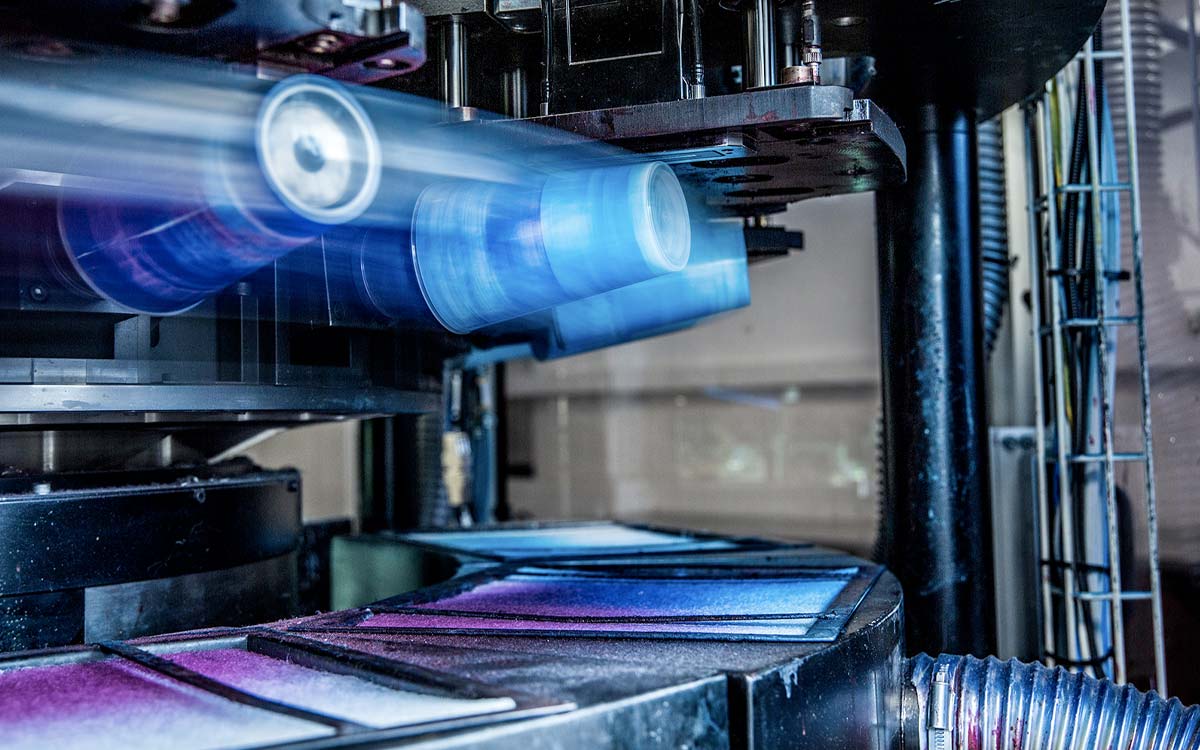

In the packaging division, GIZEH produced several billion plastic containers a year in the mid-1990s, manufacturing them in Germany, France and later Poland. Both using injection moulding and thermoforming, polystyrene and polypropylene was formed into thin-walled containers of many shapes and sizes, usually decorated using a 6-colour offset printing process. The best-sellers at this time were plastic tubs for dairy products and cups for drinks and vending machines. GIZEH also showed its creative strength in the development of two-chambered cups. An innovative decoration process, off-mould labelling, was also used for the first time.

Repositioning the GIZEH Group

A few innovations were unable to solve the underlying problems. In the mid-1990s, the GIZEH company portfolio encompassed eleven different legal entities or companies that were poorly tailored to the needs of customers and the market. Consequently, the business losses began to mount, and the future of the group seemed to be in very real danger. This was the situation when 39-year-old Ralf Jung took on the position of sole director of GIZEH-Werk GmbH. As part of his rejuvenation efforts, he repositioned the group, shut down several business areas and streamlined the portfolio.

The insolvency of a shareholder in 1996 resulted in the sale of the GIZEH Group to the Deutsche Beteiligungs AG in Frankfurt. In its efforts to achieve a good sale result, DBAG broke the group up and sold the individual business sectors to market competitors. This resulted in the legal separation of the smoking accessories division in 1997, which was sold to the Dutch Mignot & de Block Group. DBAG offered the packaging division to the current managing director Ralf Jung, who acquired the business together with his wife Jacqueline in November 1998. The position of the company at the time presented all those concerned with massive challenges:

Two operations (Bergneustadt & Wemabag / Switzerland), an empty hall in Tarnowo Podgórne, 30 million in operating losses and 450 employees. One of the most important tasks after the management buyout was the repositioning of the GIZEH Group. For this reason, efforts were concentrated on a smaller customer base (including Onken, Strothmann, Dr. Oetker, Nestlé, Mona) and the company focused on high-quality packaging solutions. This strategy already showed promise in its first year and sales were doubled by 2001. This was accompanied by an improvement in the profit situation, with a positive result posted for the first time in 2002.

A new beginning as a family firm

Now, GIZEH also offered the high flexibility of an independent family firm, with short and fast decision-making processes. But to get established in the fast lane for the long haul, it needed a convincing overall strategy, one which was found through reflection on the core competences that had been honed and practised over the decades: innovative power, process expertise and high development competence. GIZEH Verpackungen was deliberately positioned as a specialist in technically demanding packaging solutions that were at the same time tailored to the customer’s requirements. It was particularly active in the field of in-mould-labelled packaging. A number of competitors were already using the process, but GIZEH, thanks to its high technical expertise, was one of the market pioneers for the technology. Within a very short time, a large number of new orders was acquired, primarily from the fine foods industry. After an urgently needed business expansion in Bergneustadt failed, GIZEH decided to open a new site and, as many customers had already decided to move their production to the former East Germany, chose Elsterwerda in Brandenburg. In 2004, production started with four injection moulding machines. By the end of 2006, GIZEH Elsterwerda was already making a significant contribution of approximately €25 million to the groups’ turnover, which had by then risen to over €80 million.

Entry into the French market

In the meantime, the GIZEH Group had risen to second place in its market sector in Germany, and was also considered an attractive supplier by big players in the industry, such as the Nestlé Group. In 2004, Nestlé moved production from Weiding, Bavaria to France, and was looking for a capable partner. At this point, negotiations were already under way between GIZEH and the Spanish Coexpan Group regarding their factory in Angers. Coexpan’s tub business was making heavy losses, and they wanted to get rid of it. However, GIZEH saw a major opportunity in this factory in connection with the expected new business with Nestlé, and decided to acquire the operation in Beaucouzé (near Angers) in 2005. Concurrent with a more general increase in investment activities by German companies at home and abroad, GIZEH had also shown itself willing to spend. Between 2004 and 2007, the Bergneustadt-based company invested a total of around 50 million euros in new plants and technologies. In this period, turnover rose from around 55 to 99 million euros. The subsequent years, 2008 and 2009, were marked by the global economic crisis, but also by efforts at restructuring in France and growth efforts at the Brandenburg works. The Polish operation was also expanded in several stages. After a drop in sales caused by the crisis, from €99 million in 2007 to €79 million in 2009, the group returned to growth again. Particularly noteworthy here is the entry into sleeve technology and the expansion of the range in the field of PET bottles in 2009.

A technological market leader

By the end of the decade, manufacturing processes such as thermoforming, stretch blow moulding and injection moulding were available and could be combined with the decorative processes of in-mould labelling, shrink sleeving, labelling, printing and digital printing. The development process also gained an important new building block in the 2010s: a high-resolution 3D printer acquired in 2014 promised faster results and greater flexibility, allowing prototypes and designs to be made to according to individual customer requirements.

From 2017, in its role as a technological market leader, GIZEH became one of the first packaging manufacturers worldwide to offer “digital cup printing”. This is a decorative process that allows for changes in design within a few minutes, meaning reaction times can be incredibly short. The market for this was focused around cups for events that could be used and reused in various different sizes. Over time, the company has been successful in supplying not just Bundesliga clubs such as Bayern Munich and Eintracht Frankfurt, but also all major music festivals in Germany, including Rock am Ring, Rock im Park, Wacken and Hurricane. For large runs, the tried and tested in-mould labelling process is also available for decorating reusable event cups.

Responsible use of resources

GIZEH started engaging in environmental protection in the 1980s, and since then it has been dedicated to improving the ecological footprint of its production facilities. In the new millennium, these efforts were ramped up, leading to the implementation of an energy management system in 2011, which is certified to ISO 50001. Every year since then, 250,000 euros have been invested in the continuous reduction of energy consumption. In addition to increasing energy efficiency and reducing emissions, GIZEH drove the generation of green energy forward by installing two photovoltaic systems in Bergneustadt and Elsterwerda. At present, there is no alternative to a diligent and resource-efficient use of plastics, especially when it comes to achieving CO2 targets. Here, the ability to save packaging while retaining the functionality of the container plays a big role. The recycling of the empty container is already taken into consideration in the design phase. The goal is to only use materials or combinations of materials that do not negatively affect the recycling process (“design for recycling”).

A further important development for GIZEH was the foundation of a location in North America. The initial trigger for this development came from the Theo Müller Group, which opened a dairy in the State of New York and commissioned GIZEH as a supplier.

After a suitable production site had been found in nearby Brantfort (Ontario), production of Froop tubs started in 2013. Other customers were soon found, among them the neighbouring Ferrero facility, so that the rented building was soon bursting at the seams. Because of the excellent growth in Canada, the decision to build a new factory directly next to the existing location was made in 2015. This new factory started production in summer 2016.

In the first half of the 2010s, the technical competence of the GIZEH Group was further strengthened. A successful entry was made into sleeve technologies at the Bergneustadt and Tarnowo Podgórne production sites. When the company’s own tool production facility in Switzerland became obsolete, and its staff neared retirement age, it was closed and a site was chosen in Poland for a completely new location. This is now home to 10 employees who, among other things, are responsible for the production of thermoforming and injection moulds.

In parallel to this, turnover was increased between 2010 and 2016 from approx. €81.5 million to €98.3 million. The group now employs around 700 workers and the development of profits before tax is also positive. From 2011 to 2017, the previous year’s result was consistently exceeded. The growth trajectory of the group once again demanded operational extensions. For this reason, new warehouses were opened at numerous production sites.

There have also been successes in France. GIZEH Emballage Angers, part of the group since 2005, posted constant growth. After a consolidation phase, with extensive investment and the optimisation of manufacturing processes, turnover in the 2010s more than doubled. In addition, at the Angers site, the group’s largest fully automatic thermoforming facility started operation. This made GIZEH France the leader in dairy packaging in France.

The future of the family firm

Today, GIZEH Verpackungen is a technological leader in rigid plastic packaging. Despite all the changes and new directions that have been taken in its eventful history, we can observe certain constants that have furthered the company’s success over the course of a century. These include, above all, flexibility, innovation, proximity to our customers and technical expertise. As an active corporate culture, these factors have enabled GIZEH to grow from a small subsidiary to a significant medium-sized group of companies, one that will even be represented in Belarus from 2020 with its own production site. With a new generation entering the family firm, GIZEH now looks forward to the future with confidence and anticipation for the challenges to come!