When it comes to quality assurance, always being at the cutting edge of technology is a challenge that GIZEH Verpackungen is happy to rise to. The new highlight in the GIZEH measuring lab is a latest generation multi-sensor CNC measuring machine. It provides quality assurance staff with three measuring sensors in one device: optical, tactile and laser measurements.

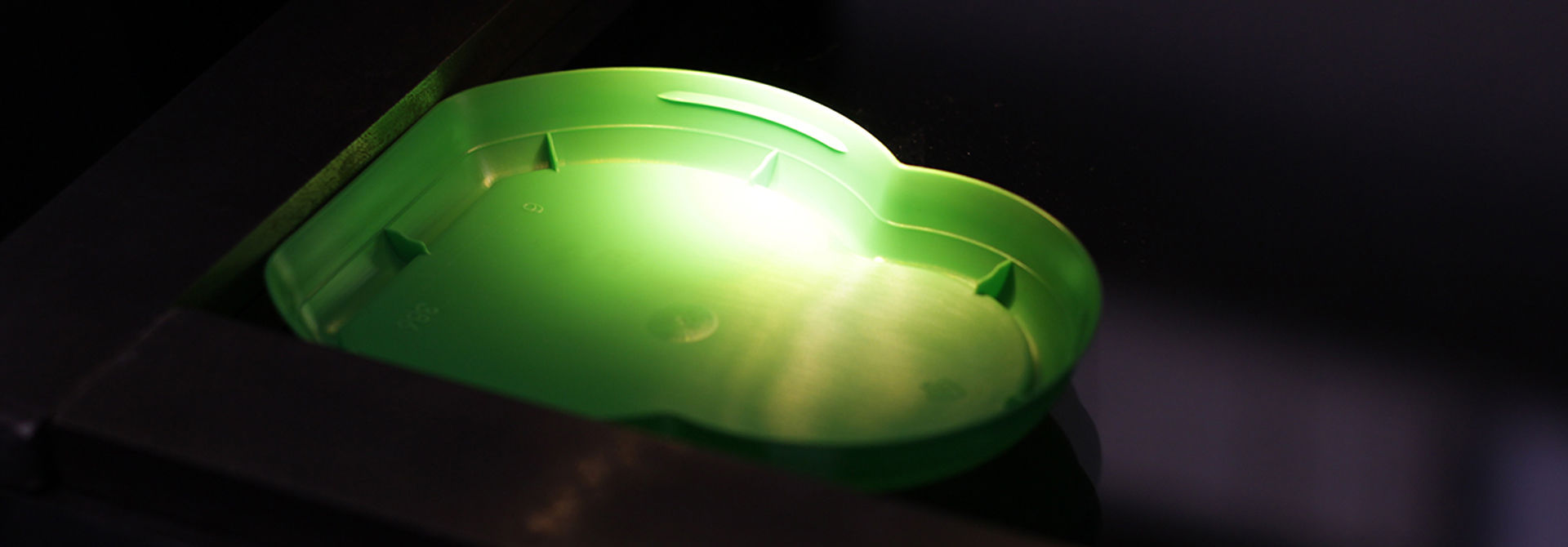

For optical technology, an object’s edges are measured using points which have been programmed beforehand. There are different lenses with universal zoom optics, as well as various focal lengths. For tactile measuring, thin sensory needles are used to determine the dimensions of a product. Using the point laser, a contour measurement is taken at height level in the optical beam path. In addition, it is possible to use a combination of optical, tactile and laser measurements.

Programming must only take place once for every GIZEH container. This can then be retrieved again at any time. Quality assurance staff are pleased: “We have a complete evaluation in no time.” Furthermore, levels of measurement and repeat accuracy are high, meaning that it is possible to achieve a more exact alignment with design specifications.