Our extensive, substantiated technology and service portfolio includes all the standard production and processing methods. Every GIZEH customer can reap the benefits of our employees who are highly skilled in all processes, as well as with the latest production equipment. This means, as your business partner, we can implement a combination of different technologies and provide our customers with, not just any solution, but the perfect solution.

Food packaging requirements are often complex and as such, extensive experience is called for. With over 50 years’ of expertise in producing food packaging, we are experts in the field and are always seeking to improve. We will find the perfect form and design for your tailor-made packaging solution.

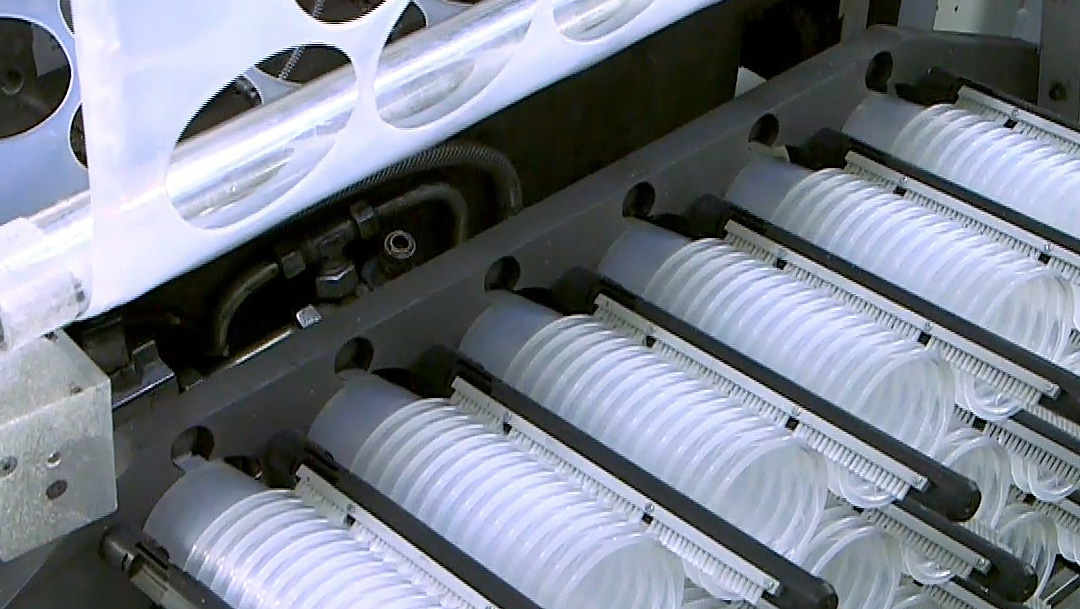

Thermoforming

GIZEH has decades of experience in thermoforming polystyrene and polypropylene. And there is a clear-cut trend: real lightweights can be produced in increasingly higher cycle times.

Thermoforming with barriers

GIZEH’s multi-layer composition in thermoforming makes it possible to create composites made of up to seven layers which excel thanks to their outstanding barrier properties, as well as their high temperature stability.

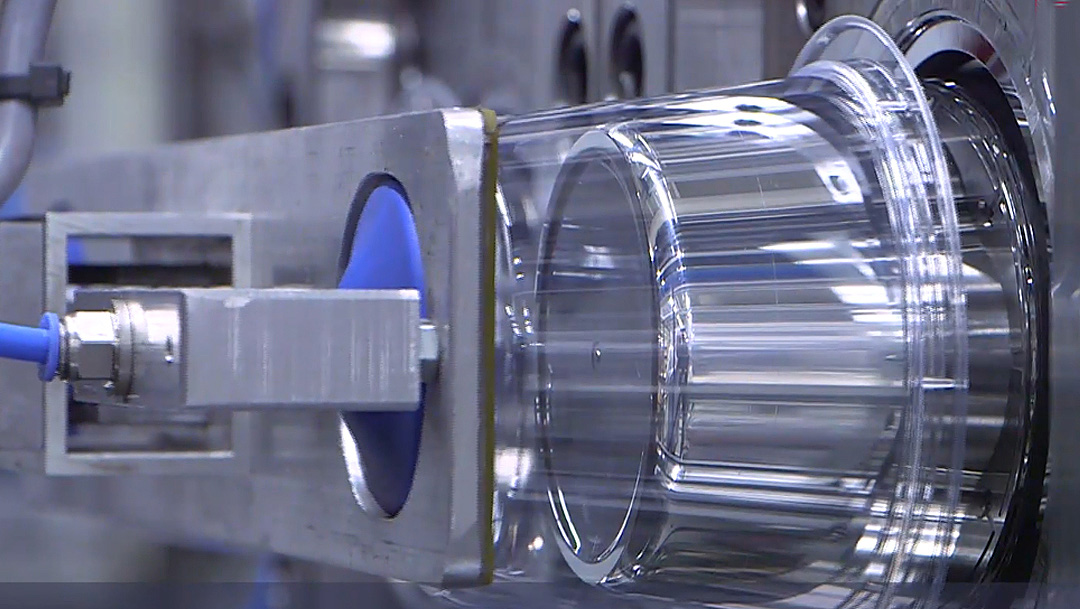

Injection stretch blow molding

GIZEH PET can produce transparent or colored PET bottles and wide neck containers using an injection stretch blow molding process. PET’s fantastic properties tick all the boxes thanks to the crystal clear transparency and brilliant surface sheen.

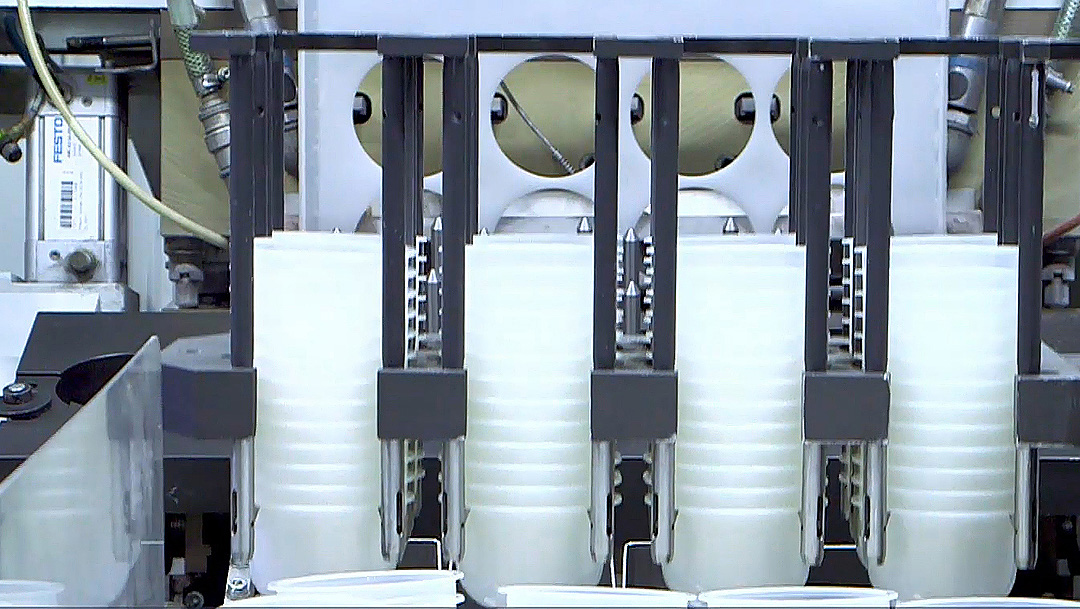

Injection molding

Injection molding is a kind of forming process. Plastic granulate is melted in the injection molding machine. The injection mold is closed and the now liquid plastic is molded into shape under high pressure.

In-mold labelling

A particular highlight of GIZEH injection molding is accessorizing the product in an in-molding labelling procedure. This involves special printed labels being automatically inserted into the injection mold before it is filled with plastic. The label then fuses with the plastic and they become one homogeneous unit.

Shrink sleeving

The advantage of sleeve decoration lies in its high level of flexibility and decorative coverage of the entire container surface. With a sleeve, products can be adorned in high-quality decoration regardless of shape, for example if sides are rounded or convex-shaped, or if the product has another individual form.

Cardboard-plastic combination

For cups with straight walls, GIZEH offers the cardboard-plastic combination, a high-quality packaging solution with reduced plastic content.

Two optimally recyclable components form a single unit:

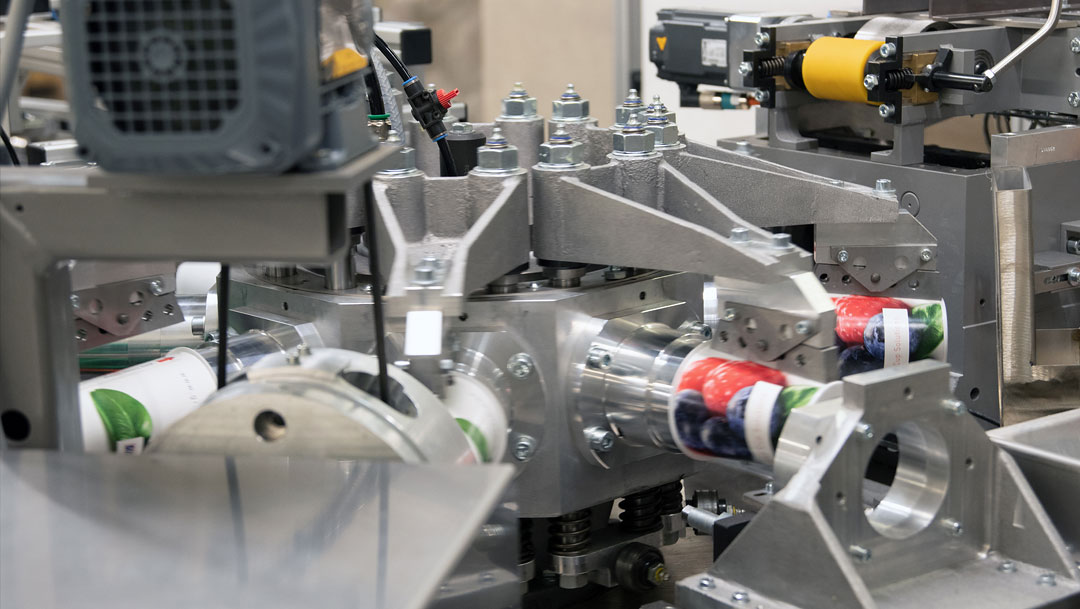

Labelling

Adhesive labels can catch your eye with realistic imagery, attention to detail and effects such as the ‘no-label’ look, or removable stickers. GIZEH can apply up to five labels to a container in one working step by using off-mold labelling.

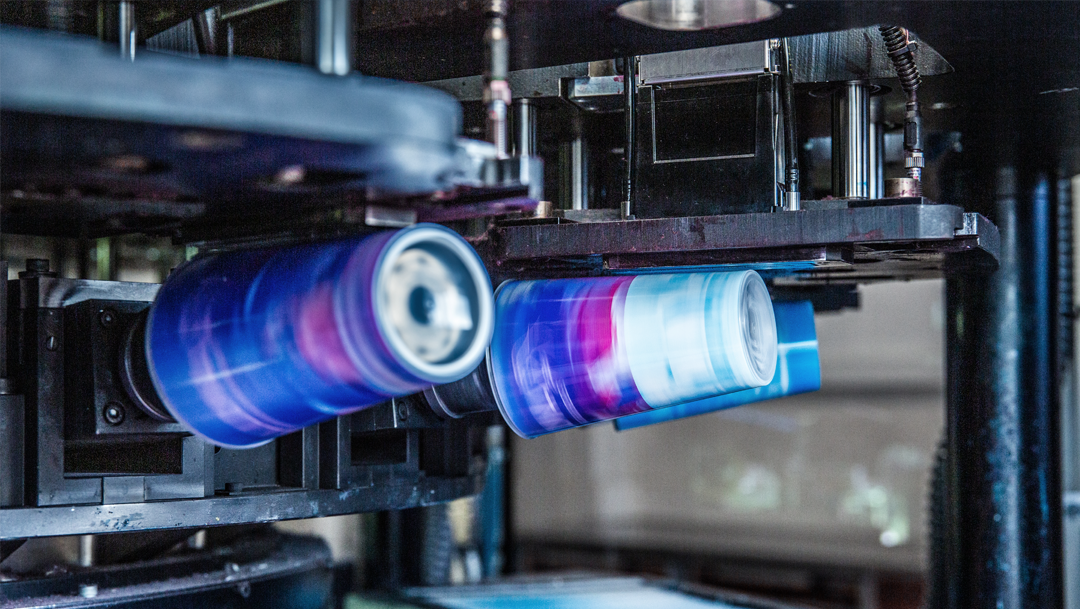

Printing

GIZEH can decorate round, square or even convex-shaped containers with up to 8 colors. Using an indirect relief printing technique, color is transferred from an embossed printing plate to a compressible rubber blanket and from there, it is then transferred to the container surface.

Digital printing

Direct digital printing on containers and lids is a completely new process and has the wow factor thanks to its photo-realistic quality and high level of color brilliance. A printing head transfers tiny droplets of ink onto the surface without coming into contact with it.

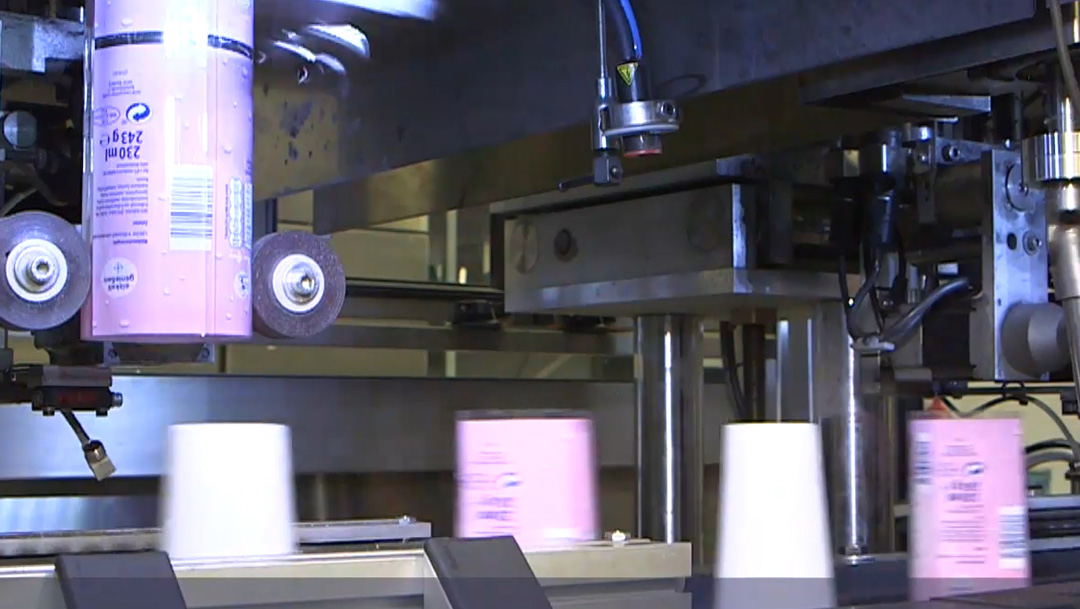

Technology – Customized for you

The latest development resulting from the GIZEH offset printing process has opened up completely new opportunities: a printed GIZEH pot can now compete with Pappmantel und Co. also in terms of visual appearance. One convincing example is that of the “Mona” and “Optimel” pots by Campina.